SOLUTIONS

We make a Difference!

To be the preferred One-Stop Integrated Factory Automation partner, the Group is underpinned with design & development team, and undergirded with vertically integrated customized sheet metal fabrication facility, precision CNC micro machining facility and equipment automation assembly processes.

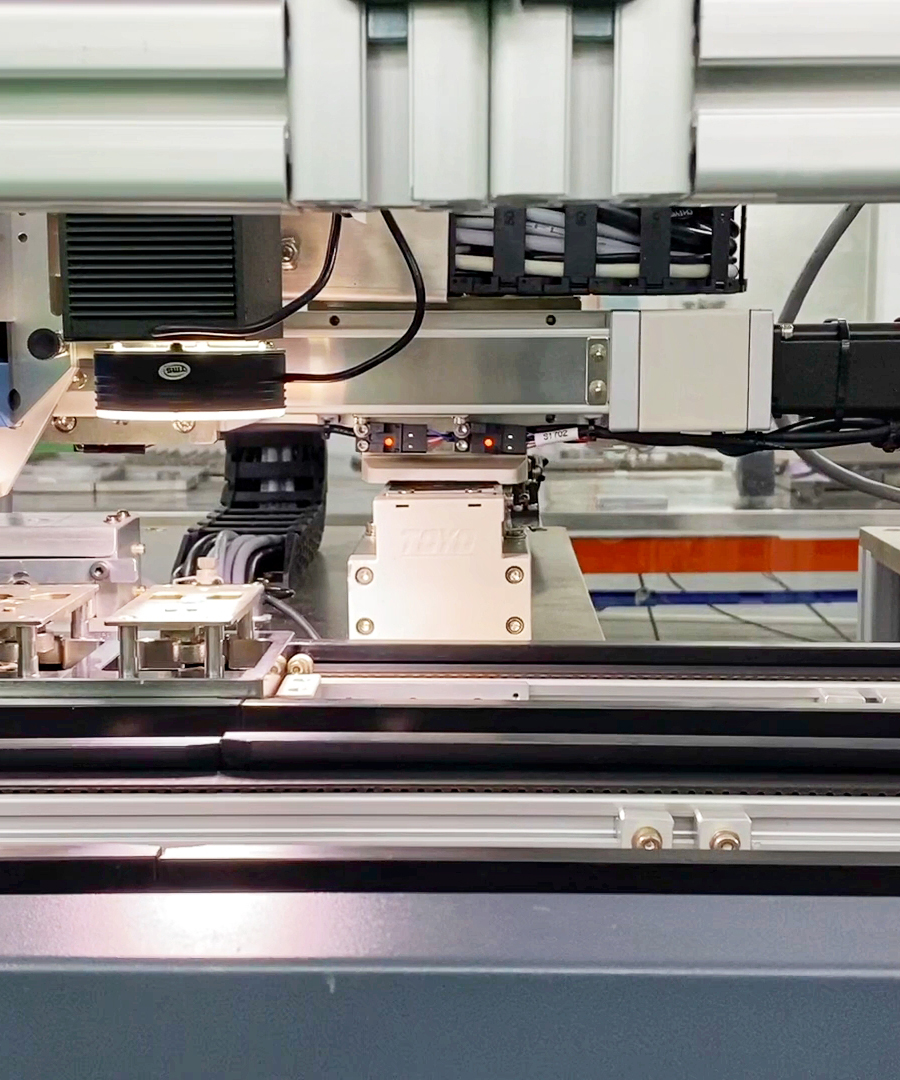

Integrated Factory and Automation Equipment Solution

We are offering integrated electronic mechanization conceptual design and the best possible integrated automation solutions to fulfill an optimally efficient, automated factory lines requirement. All our systems can be easily modularly integrated with other systems resulting in a fully automated lights-off production. We offer on-site installation and support.

Conceptualizing, designing, assembling, and commissioning of automated equipment and production line systems (comprising multiple automated equipment) for customers’ factory manufacturing lines.

Automation & Engineering Services

![]() Automation Conceptual Design

Automation Conceptual Design

![]() Engineering & Development

Engineering & Development

![]() Assembly, Test & Commissioning

Assembly, Test & Commissioning

![]() On-Site Installation & Support

On-Site Installation & Support

Automation Customization & Solutions

![]() Laser Marking Equipment

Laser Marking Equipment

![]() Smart Humidity Storage System

Smart Humidity Storage System

![]() Vacuum Chamber

Vacuum Chamber

![]() Glass Wafer Separation Equipment

Glass Wafer Separation Equipment

![]() Tools Cut Equipment

Tools Cut Equipment

![]() Robotic Handling Equipment

Robotic Handling Equipment

![]() Hard Disk Equipment

Hard Disk Equipment

![]() Assembly System

Assembly System

![]() Testing System

Testing System

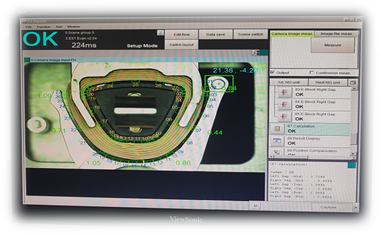

![]() Vision Inspection System

Vision Inspection System

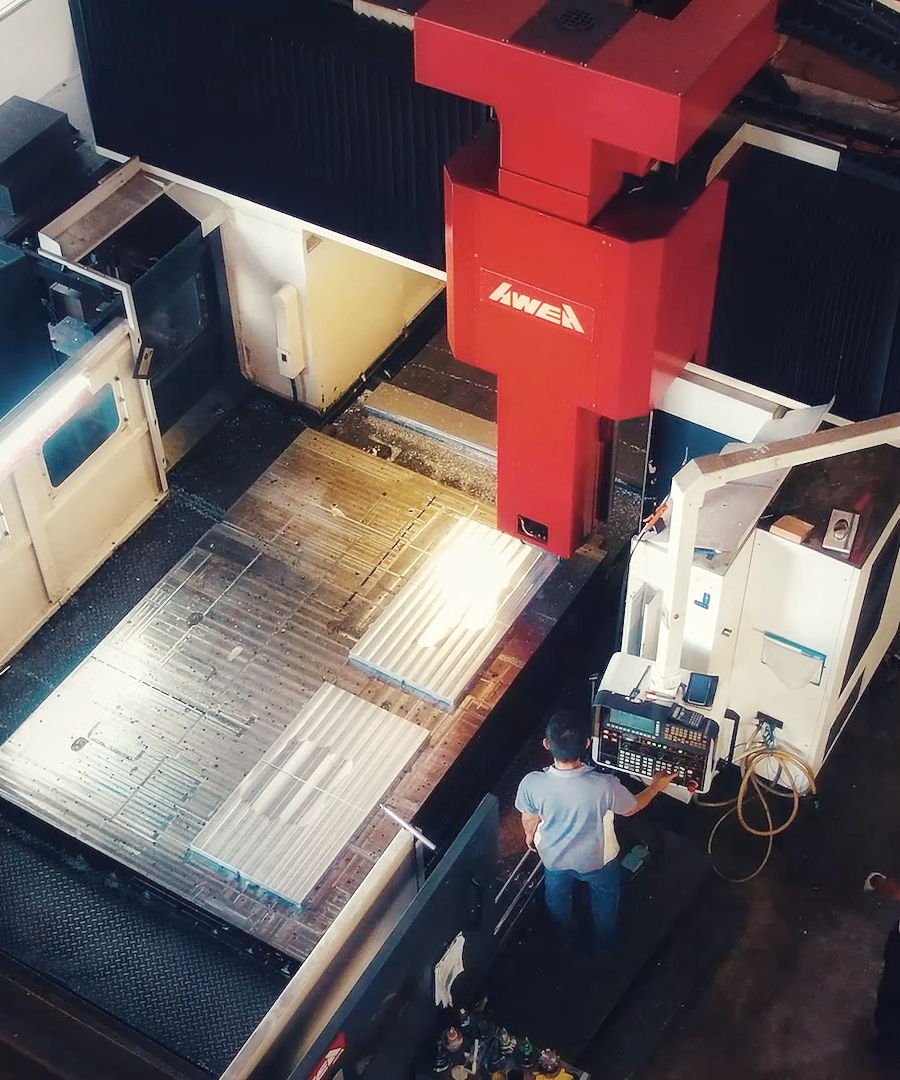

Precision CNC Micro Machining

We believe in continuous investment in advanced technology, state-of-the-art, CNC Multi-Axis machinery to be one of the cornerstones contributing to our One Stop Factory Integration of automation equipment solutions provider. Our dedication ensures that we can produce CNC machined components faster, efficiently and consistently, to the highest quality.

Metal blocks are processed into intermediate metal products. Excess metals are removed to form the precision machined components required by customers. The type of processes used are milling, turning, surface grinding and EDM cutting to produce precision machined components with micron tolerance finishes.

CNC Machining & Tooling

Customization and build-to-order CNC machining and tooling equipment.

![]() CNC Milling (3-axis)

CNC Milling (3-axis)

![]() CNC Turn-Mill

CNC Turn-Mill

![]() CNC Milling (5-axis)

CNC Milling (5-axis)

![]() CNC Turning

CNC Turning

![]() Large Format 5 Faces

Large Format 5 Faces

Milling

![]() EDM

EDM

![]() Surface Grinding

Surface Grinding

![]() CNC Wirecut

CNC Wirecut

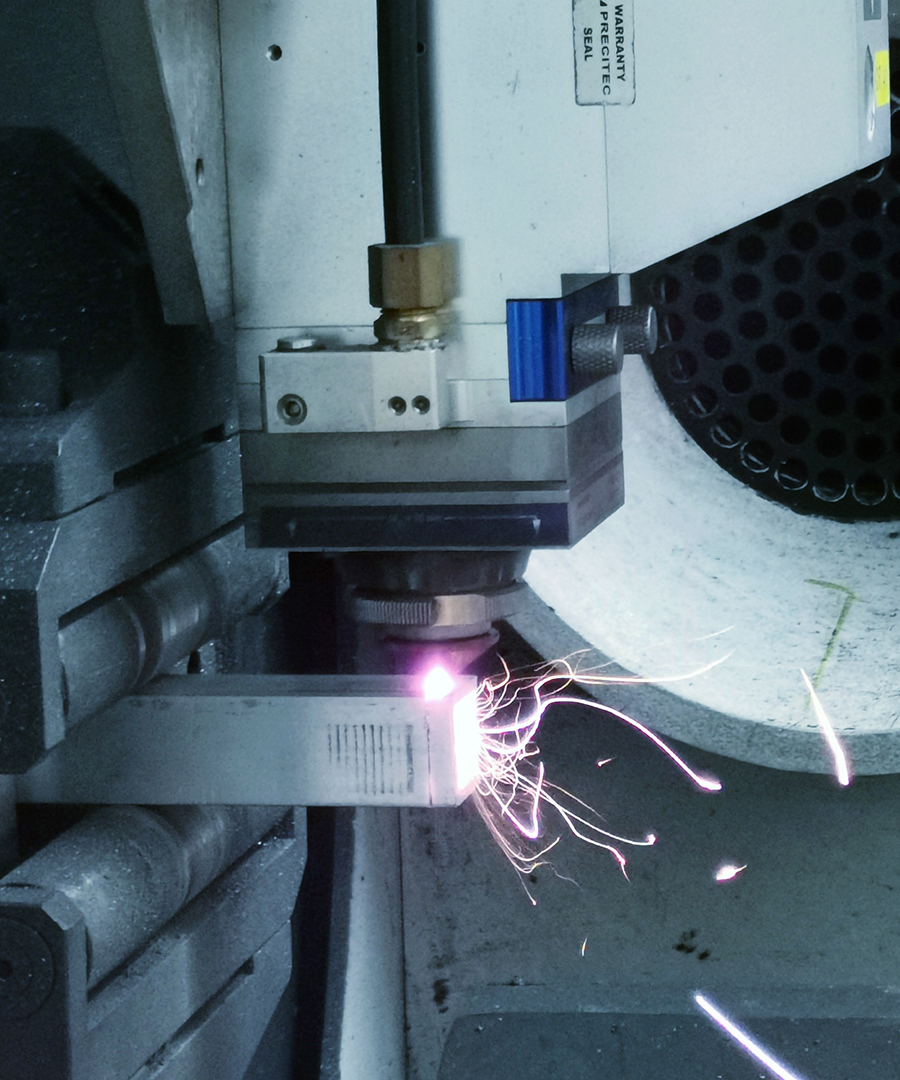

Customized Sheet Metal Fabrication

We offer the complete customized sheet metal fabrication service from design to manufacturing, namely, laser cutting, turret punch, laser tube cutting, bending, welding, deburring, and mirror polishing.

Sheet metals are processed into intermediate metal products such as metal piece-parts. The type of processes used are cutting, bending, welding, deburring and polishing with the use of machinery and equipment to achieve the design and specification required by customers.

Customized Sheet Metal Fabrication

Customized sheet metal fabrication services for medium to high volume orders.

![]() Laser Cut

Laser Cut

![]() Fibre Optic Laser

Fibre Optic Laser

![]() Deburring

Deburring

![]() Laser Cut & Punch

Laser Cut & Punch

![]() Laser, TIG, MIG, Spot Welding

Laser, TIG, MIG, Spot Welding

![]() Bending

Bending

![]() Laser Tube Cutting

Laser Tube Cutting

![]() Robotic Welding

Robotic Welding

![]() Hairline Polishing

Hairline Polishing

Mechanical & Integrated

Modular Assembly

We provide sub-module and full mechanical assembly services where we assemble metal piece-parts into machine structures, enclosures, chassis, jigs and fixtures, and many other forms of assembly in semiconductor, solar PV, E&E and other industries.

Sub-module assembly are sub-assembled products which may undergo further assembly processes. Full assembly products are finished machine structures which are ready for delivery.

Equipment / Machinery Contract Manufacturing Service

Engineering expertise to efficiently design, fabricate, assemble

and install complex assemblies, equipment, instruments, and systems.

Quality Assurance

As an ISO 9001 certified company, SFP Group of Companies strives to exceed our valued customers’ expectations through our commitment in the following policies:

OUR PRODUCTS

TMA (Touchless Mechanical Assembly)

- TMA is Touchless Manual Assembly semi auto workstation or conveyor systems.

- TMA systems integrated workstations are a hybrid of a modular conveyor line that’s combined with ergonomic workstations.

- Individual TMA workstations are joined together to create optimized, worker-paced, progressive assembly cells.

- Work in process flows through manufacturing, test, inspection, and packaging on TMA line.

- These cells can easily be customized for optimized for lean manufacturing.

- For the ultimate in simplicity and convenience, our entire system is designed to be assembled or modified

Specification

- Keyboard tray

- Rotational station/pop-up mechanism

- Scanner holder

- Pc & power gang tray

- Monitor bracket 2pcs

- Power gang 4×2

- Motion sensor & light

- MCB safety control

- Conveyor payload 20kg

- Conveyor flow direction left to right / right to left

- Station size 1000 (L) X 500 (W) X 900mm (H)

Auto Dispensing

- The Auto Dispensing is a highly accurate balance capable of automatically dispensing powders and liquids into a variety of containers.

- The ability to dispense at a minimum weight of 4 mg is unmatched by manual procedures.

- The Auto Dispensing is perfect for sample and standard preparation, capsule filling, and solution and dilution preparation.

- Automatic dispensing increases user safety, saves time, and minimizes waste of expensive and rare substances.

Specification

- Multi-angle 6-axis robot

- Stand alone system (inline or offline)

- Integrates with the dispensing head

- Repeatability -/+ 0.15mm

- Effective working area XY = 625mm X 480mm

- Rotational station/pop-up mechanism

- Conveyor payload 20kg

- Conveyor flow direction left to right / right to left

- Machine size 1500 (L) X 1200 (W) X 1850mm (H)

Auto Label Applicator

- The Auto Dispensing is a highly accurate balance capable of automatically dispensing powders and liquids into a variety of containers.

- The ability to dispense at a minimum weight of 4 mg is unmatched by manual procedures.

- The Auto Dispensing is perfect for sample and standard preparation, capsule filling, and solution and dilution preparation.

- Automatic dispensing increases user safety, saves time, and minimizes waste of expensive and rare substances.

Specification

- X,Y gantry system

- Stand alone system (inline or offline)

- Effective working area XY = 625mm X 480mm

- Label placement position accuracy +/- 0.2mm

- Label feeder up to 4 units

- Rotational station/pop-up mechanism

- Conveyor payload 20kg

- Conveyor flow direction left to right / right to left

- System size 1500 (L) X 1200 (W) X 1850mm (H)

Auto Fastening

We set standards in fastener assembly automation with advanced feeding technology.The Auto Fastening means automatic screwing plus fully automatic feeding.

- Both our compact and powerful handheld screwdrivers and our widely configurable stationary screwdriving systems follow this principle.

- The automation of screwdriving processes has only one goal to make assembly tasks quick, cost-efficient and reliable to contribute significantly to cost optimization for the customer.

- The successful Auto Fastening consistently follows this strategy and ensures the economic success of our customers.

Specification

- Scara 3-axis robot

- Stand alone system (inline or offline)

- Integrates with the Atlas Copco fastening system

- Repeatability -/+ 0.15mm

- Effective working area XY = 625mm X 480mm

- Rotational station/pop-up mechanism

- Conveyor payload 20kg

- Conveyor flow direction left to right / right to left

- Machine size 1500 (L) X 1200 (W) X 1850mm (H)

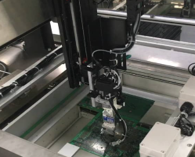

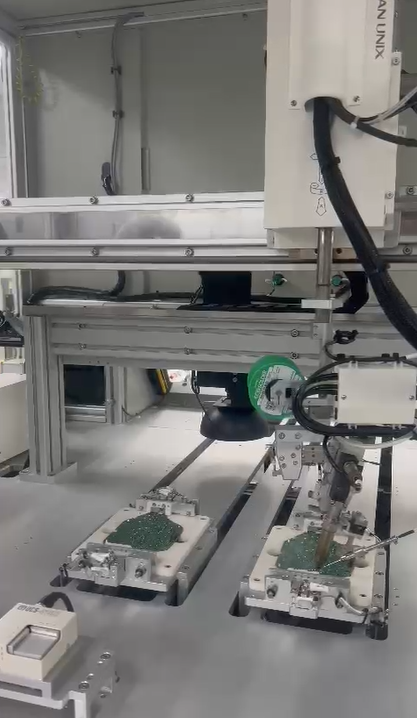

Auto Soldering System

- Our robotic soldering is a sophisticated manufacturing technique that utilizes robotic systems to perform soldering tasks in various industries, particularly in electronics and circuit board assembly.

- Instead of manual soldering, which can be time-consuming and prone to errors, robots equipped with soldering equipment are employed to complete the soldering process.

Specification

- X,Y gantry system

- Stand alone system (inline or offline)

- Integrates with the Japan Unix soldering system

- Double loader & unloader product input / output

- Conveyor payload 20kg

- Conveyor flow direction left to right / right to left

- Machine size 1500 (L) X 1200 (W) X 1850mm (H)

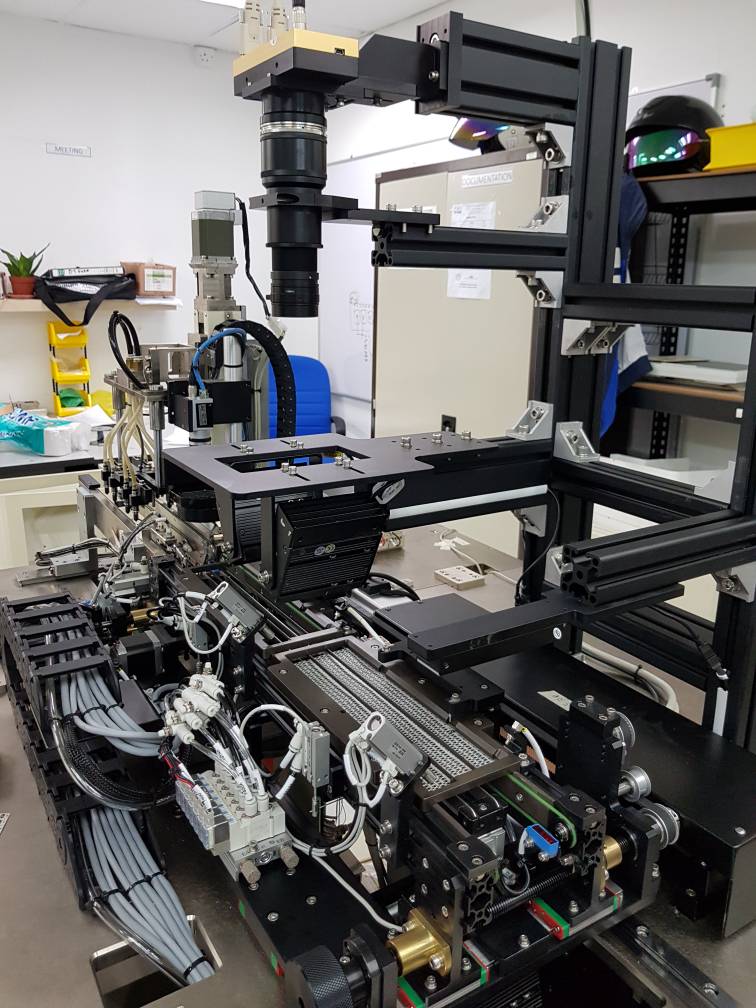

Solution Hard Disk Industry

- Manufacturing hard disk automation machines are designed to assemble a specific processes and can be very fast and efficient.

- Custom built machines are designed to run one part with a minimum number of variations.

Specification

- X,Y gantry system

- Stand alone system (inline or offline)

- Rotational station/pop-up mechanism

- Conveyor payload 20kg

- Conveyor flow direction left to right / right to left

- System size 1800 (L) X 1500 (W) X 1850mm (H)

Laser Marking Machine

- Lasers can quickly produce marks that are less than 0.005 inches deep (deeper marks are possible though those take more time). They are capable of producing a wide range of different kinds of marks, some of which can be made without weakening or damaging the material being marked. This can be especially important when you need to mark parts and surfaces that are thin or sensitive.

- Additionally, lasers can produce high resolution, detailed marks of different colors, making this marking technology the most aesthetically dynamic and pleasing marking technology available.

Specification

- X,Y gantry system

- Stand alone system (inline or offline)

- Integrates with the Keyence 3-axis laser marking system

- Conveyor payload 20kg

- Effective working area XY = 625mm X 480mm

- Conveyor flow direction left to right / right to left

- Machine size 1800 (L) X 1200 (W) X 1850mm (H)

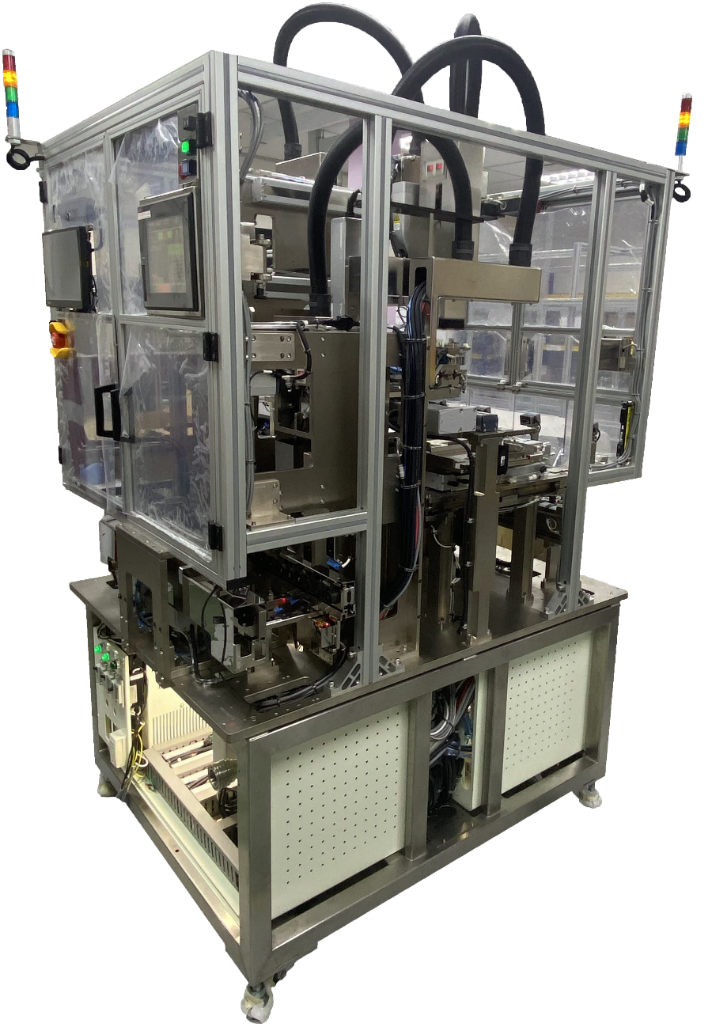

Solution for the Disk-Drive Industry

- Manufacturing hard disk automation lines are designed to assemble a specific processes and can be very fast and efficient.

- Custom built machines are designed to run one part with a minimum number of variations.

- They can also perform quality control and other tasks related to general manufacturing requirements.

Specification

- X,Y gantry system

- Stand alone system (inline or offline)

- Rotational station/pop-up mechanism

- Conveyor payload 20kg

- Conveyor flow direction left to right / right to left

- System size 1800 (L) X 1500 (W) X 1850mm (H)

Customer Satisfaction

By exceeding customers’

overall requirements.

Technical capabilities

Through design & development & product innovation.

Total Quality Management System

To enhance operational efficiency & effectiveness, resulting in quality productivity.