ABOUT US

Group Brief History

SFP Tech Group is an engineering supporting service provider with automated equipment solutions that ultimately provides customized integrated engineering setup solutions.

The history of SFP Tech Group can be traced back to the establishment of its subsidiary, SFP Technology in 2012, which started as a sheet metal fabrication with minor assembly services for the Electrical and Electronic industry.

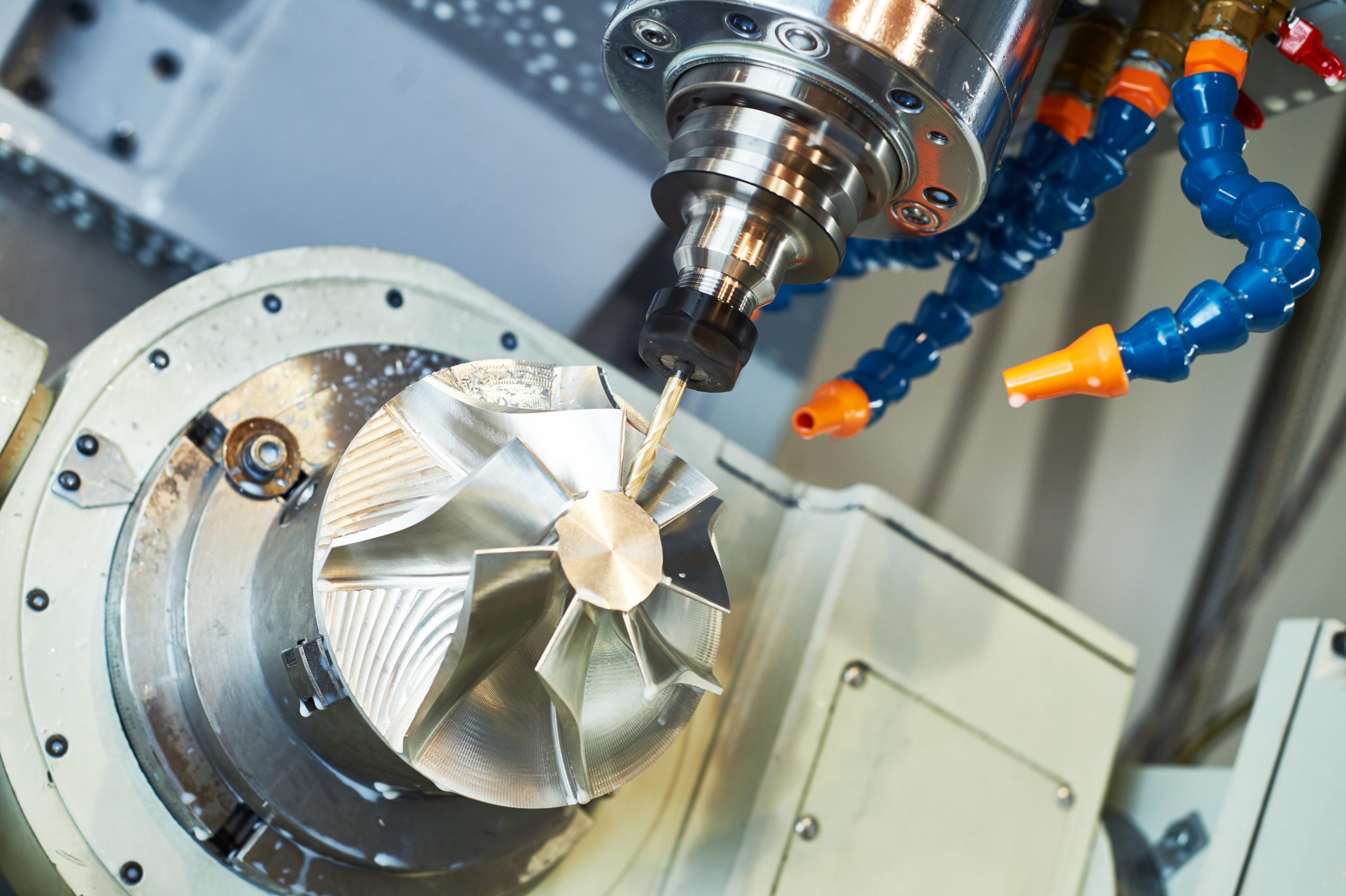

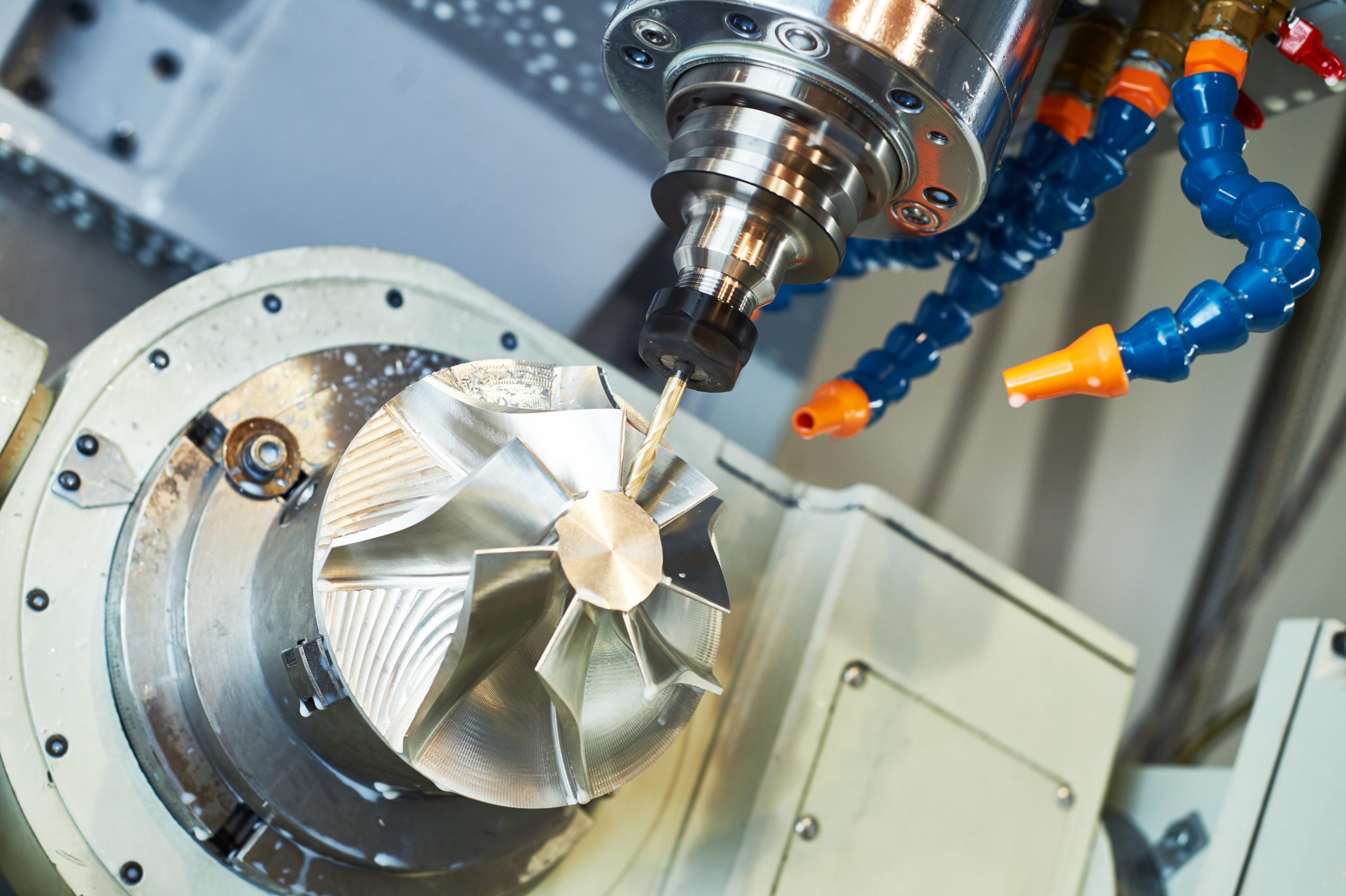

Over the years, SFP Tech Group expanded its service offerings to include CNC precision machining and mechanical assembly catering to both local and foreign customers.

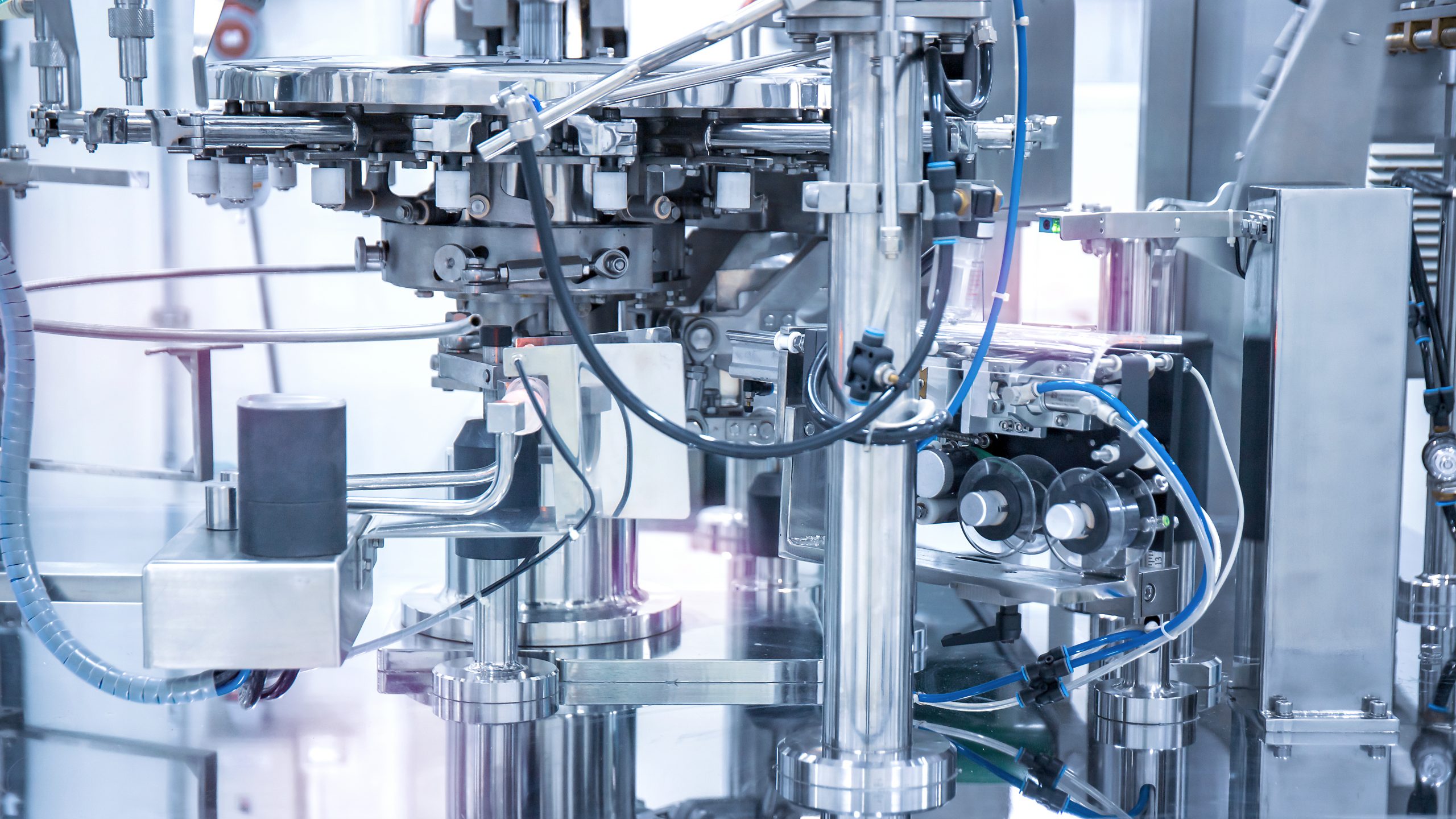

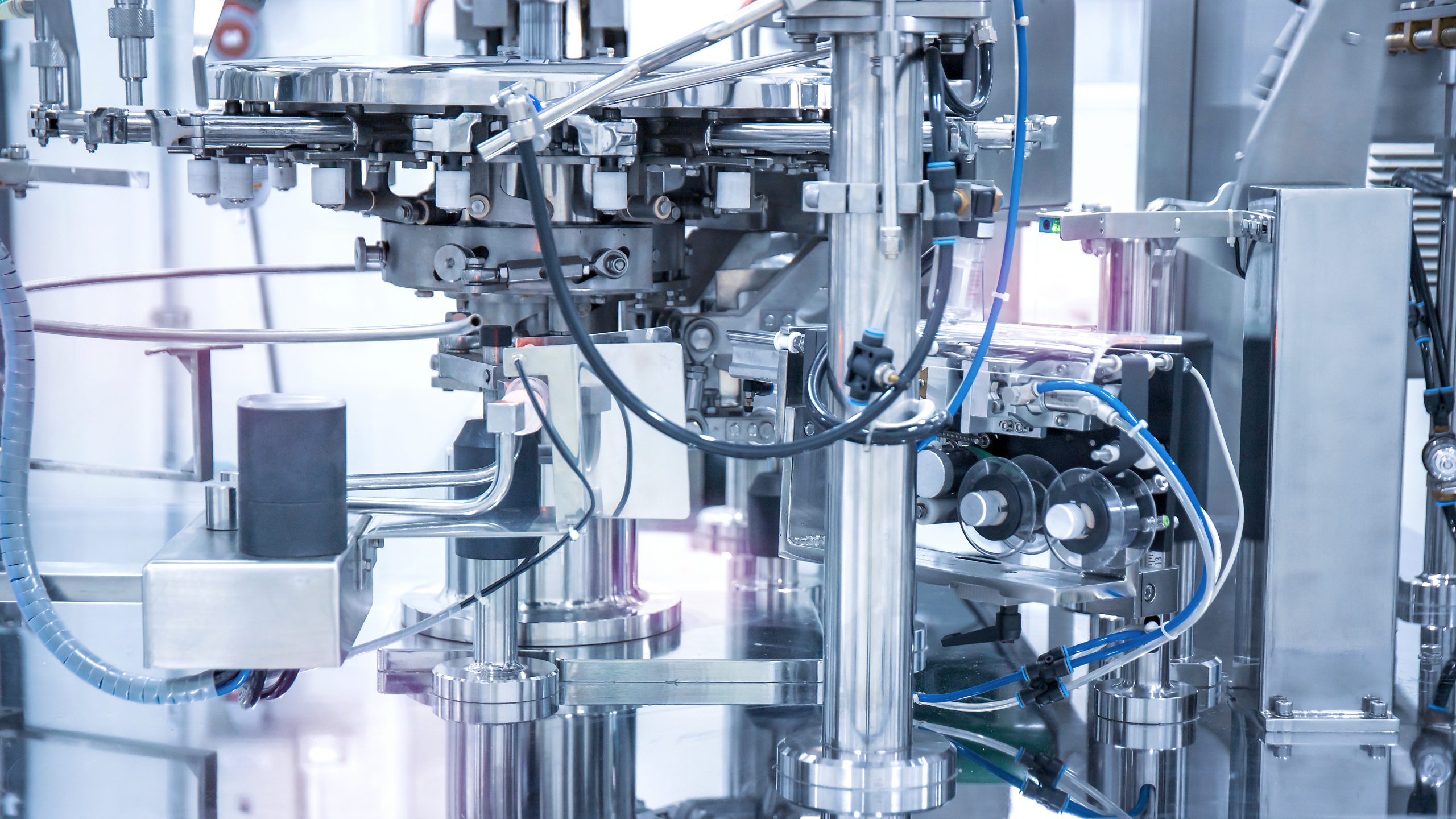

One of SFP Tech Group’s subsidiary, SFP Automation (formally known as EST Exhibit Automation), specializes in automation engineering solutions that can be customized and integrated to complete factory production lines setup.

Complementing existing approximately 150,000 square feet manufacturing space, the Group is currently in the midst of constructing a third manufacturing plant at Penang Science Park, comprising of a 3-storey detached factory building with a built up area of over 319,000 square feet.

Our Key Achievement And Milestone

INCORPORATION

SFP Technology Sdn Bhd

SERVICES

![]() Sheet Metal Fabrication

Sheet Metal Fabrication

![]() Machined Parts & Components

Machined Parts & Components

OBTAINED

![]() MIDA Pioneer Status For Design, Development and Manufacture of Semiconductor Test Head Manipulator (2015 to 2020)

MIDA Pioneer Status For Design, Development and Manufacture of Semiconductor Test Head Manipulator (2015 to 2020)

![]() Pioneer Status extended to 2025

Pioneer Status extended to 2025

CERTIFIED

![]() ISO 9001

ISO 9001

CONSTRUCTION

![]() Plant 1 Building

Plant 1 Building

ACQUISITION

![]() Plant 2 Land [ Plot 350 (A) ]

Plant 2 Land [ Plot 350 (A) ]

BUSINESS EXTENSION

![]() Solar PV, Test and Measurement Equipment Industry

Solar PV, Test and Measurement Equipment Industry

COMPLETION

![]() Plant 2 Building Completed

Plant 2 Building Completed

ACQUISITION

![]() SFP Automation Sdn Bhd

SFP Automation Sdn Bhd

SERVICES EXTENSION

![]() Integrated Factory Automation Solutions

Integrated Factory Automation Solutions![]() Laser Tube Cutting

Laser Tube Cutting![]() Capacity Increase in Multi-Geometry CNC Precision Machining

Capacity Increase in Multi-Geometry CNC Precision Machining

COMPLETION

![]() Plant 2 Building Completed

Plant 2 Building Completed

SERVICES EXTENSION

![]() Mechanical Assembly for Machine

Mechanical Assembly for Machine

Structure, Frame and Enclosures

![]() CNC Precision Machining

CNC Precision Machining

ACQUISITION

![]() Plant 1 Land [ Plot 350 (B) ]

Plant 1 Land [ Plot 350 (B) ]

SERVICES EXTENSION

![]() Invested in Laser and Turret Punching

Invested in Laser and Turret Punching

Combination Machine (MIDA Grant)

COMPLETION

![]() Plant 1 Building Completed

Plant 1 Building Completed![]() Relocated Operation into Plant 1

Relocated Operation into Plant 1

ACQUISITION

![]() Plant 3 Land [ Plot 322 ]

Plant 3 Land [ Plot 322 ]

SERVICES EXTENSION

![]() Multi-Geometry CNC Precision Machining and Grinding

Multi-Geometry CNC Precision Machining and Grinding

PUBLIC LISTING

![]() Listed on ACE Market of Bursa Malaysia

Listed on ACE Market of Bursa Malaysia

SERVICES EXTENSION

![]() Fiber Optic Laser

Fiber Optic Laser![]() Deburring

Deburring![]() Robotic Welding

Robotic Welding![]() D&D Robotic Deep Learning Vision

D&D Robotic Deep Learning Vision![]() Automatic Fastening Machine

Automatic Fastening Machine![]() Laser Soldering Machine

Laser Soldering Machine

CORPORATE

SFP Integration Pte Ltd (Singapore)

COMPLETION

Class 10K (ISO 7) Clean Room

SERVICES EXTENSION

![]() Value Analysis Value Engineering (VAVE)

Value Analysis Value Engineering (VAVE)![]() Tooling & Test Equipment Design and Fabrication

Tooling & Test Equipment Design and Fabrication![]() Global Supply Chain & Vertically Integrated Supply Chain Model

Global Supply Chain & Vertically Integrated Supply Chain Model![]() Customer Documentation Cleanup

Customer Documentation Cleanup

2012

INCORPORATION

SFP Technology Sdn Bhd

SERVICES

![]() Sheet Metal Fabrication

Sheet Metal Fabrication

![]() Machined Parts & Components

Machined Parts & Components

2013

SERVICES EXTENSION

![]() Mechanical Assembly for Machine Structure, Frame and Enclosures

Mechanical Assembly for Machine Structure, Frame and Enclosures

![]() CNC Machining

CNC Machining

2015

OBTAINED

![]() MIDA Pioneer Status For Design, Development and Manufacture of Semiconductor Test Head Manipulator (2015 to 2020)

MIDA Pioneer Status For Design, Development and Manufacture of Semiconductor Test Head Manipulator (2015 to 2020)

![]() Pioneer Status extended to 2025

Pioneer Status extended to 2025

2016

ACQUISITION

![]() Plant 1 Land [ Plot 350 (B) ]

Plant 1 Land [ Plot 350 (B) ]

SERVICES EXTENSION

![]() Invested in Laser and Turret Punching Combination Machine (MIDA Grant)

Invested in Laser and Turret Punching Combination Machine (MIDA Grant)

2017

CERTIFIED

![]() ISO 9001

ISO 9001

CONSTRUCTION

![]() Plant 1 Building

Plant 1 Building

ACQUISITION

![]() Plant 2 Land [ Plot 350 (A) ]

Plant 2 Land [ Plot 350 (A) ]

BUSINESS EXTENSION

![]() Solar PV, Test and Measurement Equipment Industry

Solar PV, Test and Measurement Equipment Industry

2018

COMPLETION

![]() Plant 1 Building Completed

Plant 1 Building Completed![]() Relocated Operation into Plant 1

Relocated Operation into Plant 1

2019

COMPLETION

![]() Plant 2 Building Completed

Plant 2 Building Completed

2020

ACQUISITION

![]() Plant 3 Land [ Plot 322 ]

Plant 3 Land [ Plot 322 ]

SERVICES EXTENSION

![]() CNC 5-Axis Machining and Grinding

CNC 5-Axis Machining and Grinding

2021

ACQUISITION

![]() EST Exhibit Automation Sdn Bhd

EST Exhibit Automation Sdn Bhd

SERVICES EXTENSION

![]() Integrated Factory Automation Solutions

Integrated Factory Automation Solutions![]() Laser Tube Cutting

Laser Tube Cutting![]() Capacity Increase in CNC 5-Axis Precision Machining

Capacity Increase in CNC 5-Axis Precision Machining

CONSTRUCTION

![]() Plant 3 Building (To Complete Q2 2022)

Plant 3 Building (To Complete Q2 2022)

2022

PUBLIC LISTING

![]() Listed on ACE market

Listed on ACE market

SERVICES EXTENSION

![]() Fiber Optic Laser

Fiber Optic Laser

CONSTRUCTION

![]() Plant 3 Building

Plant 3 Building

Group Core Value

Cornerstone to our success today is our strong belief in Sincerity in business partnership, Fast track and cost effective technology solution and People oriented leadership.

Group Vision Statement

Group Quality Policy

We strive for optimum Customer Satisfaction through exceeding customers’ overall requirements,

via breakthrough technical capabilities, services, product innovation and

Total Quality Management System enhancing operational efficiency & effectiveness.

Group Core Competency

![]() Expertise to conceptualize, design and develop, and

Expertise to conceptualize, design and develop, and

manufacture integrated factory and automation

equipment solutions.

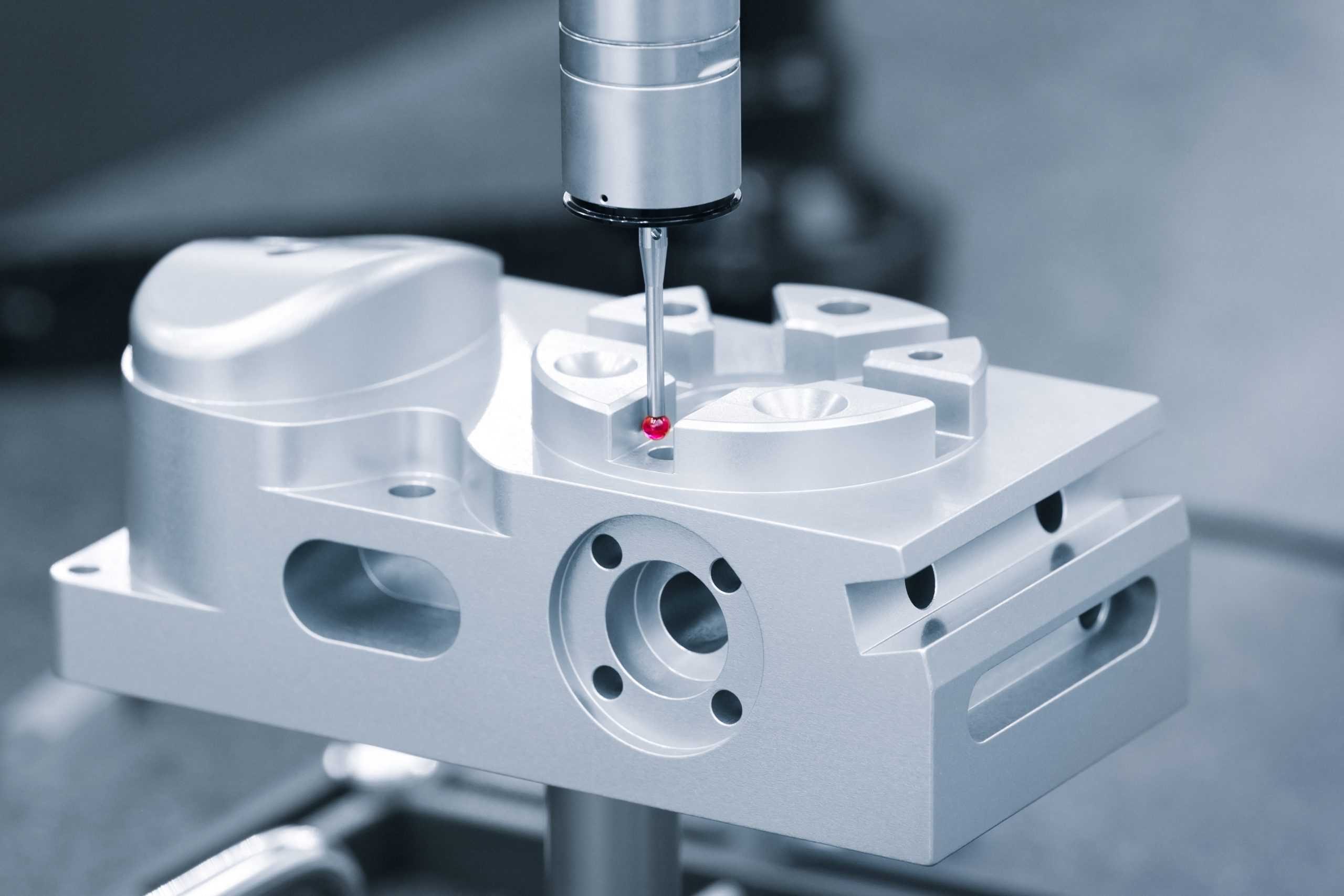

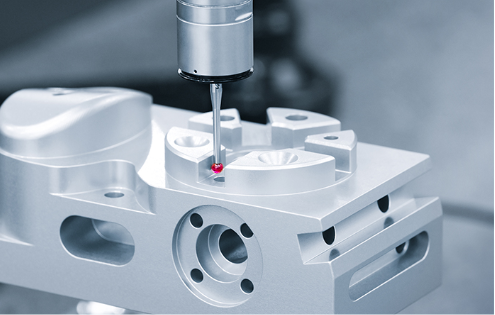

![]() Engineering capability to customize and process

Engineering capability to customize and process

complex precision metal parts.

![]() Operation agility to manage High-Mix-Low-Volume

Operation agility to manage High-Mix-Low-Volume

and High-Mix-High-Volume customer orders with

Quick Turnaround Time.